What are the Popular Low-Voltage Capacitor Models?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving various roles such as energy storage, filtering, and signal coupling. Among the different types of capacitors, low-voltage capacitors are particularly significant due to their widespread use in consumer electronics, automotive applications, and industrial equipment. This article aims to provide an overview of popular low-voltage capacitor models, their characteristics, applications, and factors to consider when selecting the right capacitor for specific needs.

II. Understanding Low-Voltage Capacitors

A. What are Low-Voltage Capacitors?

Low-voltage capacitors are capacitors designed to operate at voltage ratings typically below 50V. They are essential in applications where high voltage is not a concern, allowing for compact designs and cost-effective solutions.

1. Voltage Ratings and Classifications

Low-voltage capacitors are classified based on their voltage ratings, which indicate the maximum voltage the capacitor can handle without risk of failure. Common voltage ratings for low-voltage capacitors include 6.3V, 10V, 16V, 25V, and 35V.

2. Common Applications

These capacitors are commonly found in consumer electronics, such as smartphones, tablets, and laptops, as well as in automotive electronics, industrial machinery, and telecommunications equipment.

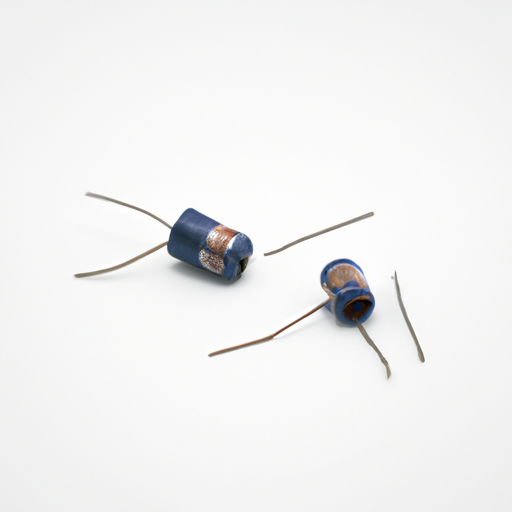

B. Types of Low-Voltage Capacitors

Low-voltage capacitors come in various types, each with unique characteristics and applications:

1. Ceramic Capacitors

Ceramic capacitors are widely used due to their small size, low cost, and excellent stability. They are available in different dielectric types, with X7R and X5R being the most common for low-voltage applications.

2. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors known for their high capacitance values. They are often used in power supply circuits and audio applications.

3. Film Capacitors

Film capacitors are known for their reliability and stability. They are available in various materials, including polyester and polypropylene, making them suitable for a range of applications.

4. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance in a small package. They are often used in applications requiring stable performance over a wide temperature range.

III. Key Characteristics of Low-Voltage Capacitors

When selecting low-voltage capacitors, several key characteristics must be considered:

A. Capacitance Values

Capacitance is a measure of a capacitor's ability to store electrical energy. Low-voltage capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF).

B. Voltage Ratings

The voltage rating is crucial for ensuring the capacitor operates safely within its limits. Exceeding the voltage rating can lead to capacitor failure, which may damage the circuit.

C. Tolerance Levels

Tolerance indicates how much the actual capacitance can vary from the stated value. Common tolerance levels for low-voltage capacitors range from ±5% to ±20%.

D. Temperature Coefficients

Temperature coefficients describe how capacitance changes with temperature. Different dielectric materials have different temperature coefficients, affecting performance in varying environmental conditions.

E. Equivalent Series Resistance (ESR)

ESR is a measure of the resistance encountered by the capacitor when AC signals pass through it. Low ESR is desirable in applications where high-frequency performance is critical.

IV. Popular Low-Voltage Capacitor Models

A. Ceramic Capacitors

1. X7R and X5R Types

X7R and X5R are popular dielectric types for ceramic capacitors, offering good capacitance stability over a range of temperatures and voltages.

2. Popular Models

Murata GRM Series: Known for their reliability and compact size, these capacitors are widely used in various electronic devices.

TDK C3216 Series: These capacitors offer excellent performance in high-frequency applications, making them suitable for RF circuits.

B. Electrolytic Capacitors

1. Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are commonly used for their high capacitance values and affordability.

2. Popular Models

Nichicon UHE Series: These capacitors are known for their long life and low ESR, making them ideal for power supply applications.

Panasonic EEU Series: Renowned for their reliability, these capacitors are widely used in consumer electronics and industrial applications.

C. Film Capacitors

1. Polyester and Polypropylene Types

Polyester and polypropylene film capacitors are known for their stability and low loss characteristics.

2. Popular Models

WIMA MKS Series: These capacitors are widely used in audio and power applications due to their excellent performance.

KEMET R82 Series: Known for their reliability and versatility, these capacitors are suitable for various applications, including automotive and industrial.

D. Tantalum Capacitors

1. Solid Tantalum Capacitors

Solid tantalum capacitors are known for their high capacitance and small size, making them ideal for compact designs.

2. Popular Models

KEMET T491 Series: These capacitors are known for their reliability and stability, making them suitable for a wide range of applications.

AVX TPS Series: Renowned for their high performance and low ESR, these capacitors are commonly used in power management applications.

V. Applications of Low-Voltage Capacitors

Low-voltage capacitors find applications in various fields, including:

A. Consumer Electronics

In consumer electronics, low-voltage capacitors are used in power supply circuits, audio equipment, and signal processing.

B. Automotive Applications

In automotive electronics, these capacitors are used in power management systems, infotainment systems, and safety features.

C. Industrial Equipment

Low-voltage capacitors are essential in industrial machinery for power supply filtering, motor control, and signal coupling.

D. Telecommunications

In telecommunications, low-voltage capacitors are used in signal processing, filtering, and power supply circuits.

E. Power Supply Circuits

Low-voltage capacitors play a critical role in power supply circuits, providing energy storage and filtering to ensure stable operation.

VI. Factors to Consider When Choosing Low-Voltage Capacitors

When selecting low-voltage capacitors, several factors should be considered:

A. Application Requirements

Understanding the specific requirements of the application, such as capacitance value, voltage rating, and ESR, is crucial for selecting the right capacitor.

B. Environmental Conditions

Consider the environmental conditions in which the capacitor will operate, including temperature, humidity, and potential exposure to chemicals.

C. Size and Form Factor

The physical size and form factor of the capacitor can impact the overall design of the circuit, making it essential to choose a capacitor that fits the available space.

D. Cost Considerations

Cost is always a factor in component selection. Balancing performance and cost is essential to ensure the project remains within budget.

VII. Conclusion

Low-voltage capacitors are vital components in modern electronic circuits, offering a range of options to meet various application needs. From ceramic to tantalum capacitors, each type has its unique characteristics and popular models that cater to different requirements. Understanding the key characteristics, applications, and selection criteria for low-voltage capacitors can help engineers and designers make informed decisions, ensuring optimal performance in their electronic designs.

VIII. References

- Manufacturer datasheets and specifications

- Industry standards and guidelines

- Technical articles on capacitor technology and applications

This comprehensive overview of popular low-voltage capacitor models provides valuable insights for anyone involved in electronics design, helping to navigate the diverse landscape of capacitor options available today.