What are the Mainstream Models of Fan Capacitors?

I. Introduction

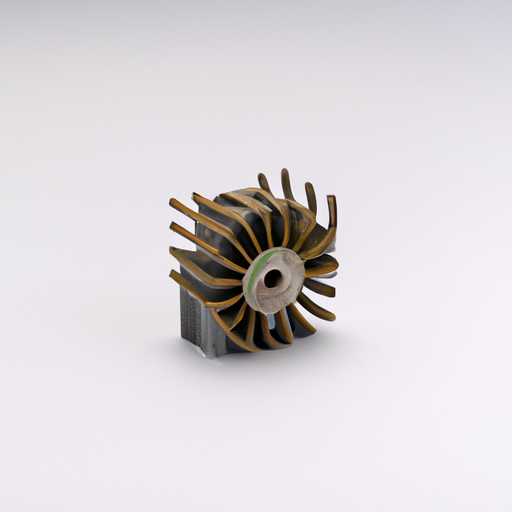

A. Definition of Fan Capacitors

Fan capacitors are electrical components that store and release electrical energy in a circuit, playing a crucial role in the operation of various types of fans, including ceiling fans, exhaust fans, and HVAC systems. These capacitors help in starting the motor and maintaining its operation, ensuring that fans run efficiently and effectively.

B. Importance of Fan Capacitors in Electrical Systems

In electrical systems, fan capacitors are essential for providing the necessary phase shift to start and run single-phase motors. Without these capacitors, motors would struggle to start, leading to inefficiency and potential damage. Therefore, understanding fan capacitors is vital for anyone involved in electrical engineering, HVAC maintenance, or DIY home projects.

C. Overview of the Article

This article will delve into the various types of fan capacitors, their functions, mainstream models from popular brands, and factors to consider when selecting and maintaining these components. By the end, readers will have a comprehensive understanding of fan capacitors and their significance in electrical systems.

II. Understanding Fan Capacitors

A. What is a Capacitor?

1. Basic Principles of Capacitance

A capacitor is a two-terminal passive electronic component that stores electrical energy in an electric field. The ability of a capacitor to store charge is measured in farads (F), with most fan capacitors typically rated in microfarads (µF). The basic principle of capacitance involves the separation of positive and negative charges, which creates an electric field between the capacitor's plates.

2. Role of Capacitors in Electrical Circuits

Capacitors play a vital role in electrical circuits by smoothing out voltage fluctuations, filtering signals, and providing the necessary phase shift for AC motors. In fan applications, capacitors are crucial for starting and running the motor efficiently.

B. Types of Capacitors

1. Electrolytic Capacitors

Electrolytic capacitors are polarized capacitors that offer high capacitance values in a relatively small size. They are commonly used in power supply circuits and are not typically used in fan applications due to their polarity sensitivity.

2. Ceramic Capacitors

Ceramic capacitors are non-polarized and are known for their stability and reliability. They are often used in high-frequency applications and can be found in various electronic devices, including fans.

3. Film Capacitors

Film capacitors are made from thin plastic films and are known for their excellent performance in AC applications. They are commonly used in fan motors due to their reliability and ability to handle high voltages.

4. Tantalum Capacitors

Tantalum capacitors are also polarized and offer high capacitance in a small package. They are used in specialized applications but are less common in fan systems.

III. Function of Fan Capacitors

A. Starting Capacitors

1. Purpose and Operation

Starting capacitors provide an initial boost of energy to the motor, allowing it to overcome inertia and start spinning. They are typically used in applications where high starting torque is required.

2. Common Applications

Starting capacitors are commonly found in air conditioning units, refrigeration systems, and larger fans that require a significant amount of torque to start.

B. Run Capacitors

1. Purpose and Operation

Run capacitors are used to improve the efficiency of the motor during operation. They remain in the circuit while the motor is running, providing a continuous phase shift that enhances performance.

2. Common Applications

Run capacitors are widely used in HVAC systems, ceiling fans, and other applications where motors need to run continuously and efficiently.

C. Dual Capacitors

1. Definition and Functionality

Dual capacitors combine both starting and running functions in a single unit. They are designed to provide the necessary boost for starting and maintain efficiency during operation.

2. Applications in HVAC Systems

Dual capacitors are commonly used in HVAC systems, where both starting and running capabilities are essential for optimal performance.

IV. Mainstream Models of Fan Capacitors

A. Overview of Popular Brands

Several brands are recognized for their quality and reliability in manufacturing fan capacitors. Some of the most popular brands include:

1. GE (General Electric)

GE is a well-known brand in the electrical industry, offering a range of capacitors suitable for various applications.

2. Siemens

Siemens is another reputable brand that provides high-quality capacitors, known for their durability and performance.

3. Panasonic

Panasonic is recognized for its innovative technology and reliable capacitors, making it a popular choice among consumers.

4. Vishay

Vishay is a leading manufacturer of electronic components, including capacitors, known for their precision and quality.

B. Specific Models

1. GE 97F

Specifications: The GE 97F is a dual capacitor with a capacitance value of 5 µF and a voltage rating of 370V.

Applications: It is commonly used in air conditioning units and other HVAC applications.

2. Siemens 6ED1 052-1FB00-0BA0

Specifications: This model features a capacitance of 10 µF and a voltage rating of 450V.

Applications: It is suitable for various fan and motor applications, providing reliable performance.

3. Panasonic ECQ-U Series

Specifications: The ECQ-U series offers a range of capacitance values, typically from 1 µF to 10 µF, with voltage ratings up to 630V.

Applications: These capacitors are ideal for use in ceiling fans and other household appliances.

4. Vishay 1812 Series

Specifications: The Vishay 1812 series capacitors come with capacitance values ranging from 0.1 µF to 10 µF and voltage ratings of 250V to 1000V.

Applications: They are widely used in various electronic applications, including fans and HVAC systems.

V. Factors to Consider When Choosing Fan Capacitors

When selecting fan capacitors, several factors should be taken into account:

A. Voltage Rating

The voltage rating indicates the maximum voltage the capacitor can handle. It is crucial to choose a capacitor with a voltage rating higher than the operating voltage of the fan.

B. Capacitance Value

The capacitance value determines the amount of energy the capacitor can store. It is essential to select a capacitor with the correct capacitance value for the specific application.

C. Temperature Rating

Capacitors have temperature ratings that indicate their operating limits. Choosing a capacitor with an appropriate temperature rating ensures reliable performance in various environmental conditions.

D. Physical Size and Mounting Options

The physical size and mounting options of the capacitor should be compatible with the fan's design. Ensure that the selected capacitor fits within the available space and can be securely mounted.

E. Application-Specific Requirements

Different applications may have specific requirements, such as high starting torque or continuous operation. Understanding these requirements will help in selecting the right capacitor.

VI. Installation and Maintenance of Fan Capacitors

A. Safety Precautions

When working with fan capacitors, safety is paramount. Always disconnect power before handling capacitors, and use appropriate personal protective equipment.

B. Installation Guidelines

Follow the manufacturer's instructions for installation, ensuring that the capacitor is connected correctly to avoid damage to the fan or capacitor.

C. Maintenance Tips

Regular maintenance can extend the life of fan capacitors. Check for signs of wear, such as bulging or leaking, and replace capacitors as needed.

D. Signs of Failure and Replacement

Common signs of capacitor failure include humming noises, reduced fan speed, or the fan not starting at all. If any of these symptoms occur, it may be time to replace the capacitor.

VII. Conclusion

A. Recap of the Importance of Fan Capacitors

Fan capacitors are essential components in electrical systems, providing the necessary energy to start and run motors efficiently. Understanding their function and selection criteria is crucial for anyone involved in electrical work.

B. Summary of Mainstream Models

Popular brands such as GE, Siemens, Panasonic, and Vishay offer a range of reliable fan capacitors, each with specific models suited for various applications.

C. Final Thoughts on Selection and Maintenance

Choosing the right fan capacitor involves considering factors such as voltage rating, capacitance value, and application-specific requirements. Regular maintenance and timely replacement can ensure optimal performance and longevity of fan systems.

VIII. References

A. List of Sources for Further Reading

1. "Capacitors: Principles and Applications" - Electrical Engineering Textbook

2. Manufacturer datasheets for GE, Siemens, Panasonic, and Vishay capacitors.

B. Industry Standards and Guidelines

1. National Electrical Manufacturers Association (NEMA) guidelines on capacitor usage.

2. Institute of Electrical and Electronics Engineers (IEEE) standards for capacitor applications.

This comprehensive overview of fan capacitors provides valuable insights into their types, functions, mainstream models, and essential considerations for selection and maintenance. Whether you are a professional or a DIY enthusiast, understanding fan capacitors will enhance your knowledge and skills in electrical systems.