What Industries Do Standard Capacitors Include?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. Defined as passive electrical components, standard capacitors are characterized by their ability to store electrical energy in an electric field. They play a crucial role in various applications, from filtering signals to stabilizing voltage and power supply. As technology continues to advance, the demand for capacitors has surged across multiple industries. This blog post will explore the diverse industries that utilize standard capacitors, highlighting their significance and the innovations shaping their future.

II. Understanding Standard Capacitors

A. Types of Standard Capacitors

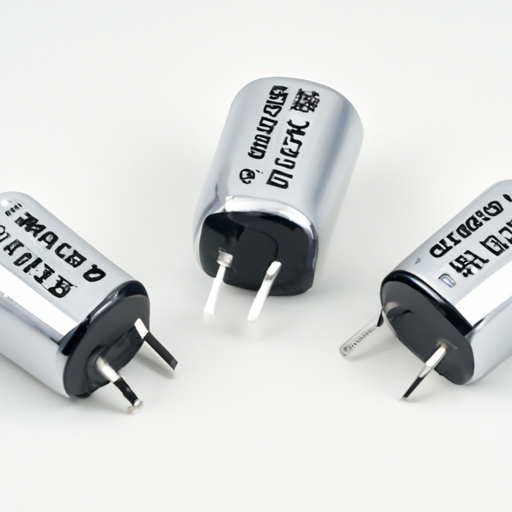

Standard capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Known for their small size and high stability, ceramic capacitors are widely used in high-frequency applications. They are often found in RF circuits and decoupling applications.

2. **Electrolytic Capacitors**: These capacitors are polarized and typically used for applications requiring high capacitance values, such as power supply filtering. They are common in audio equipment and power electronics.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their reliability and low loss. They are often used in applications requiring precision, such as timing circuits and audio equipment.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are used in applications where space is limited, such as in mobile devices and military equipment.

B. Key Characteristics and Specifications

When selecting a capacitor, several key characteristics must be considered:

1. **Capacitance Value**: This indicates the amount of charge a capacitor can store, measured in farads (F). Different applications require different capacitance values.

2. **Voltage Rating**: This specifies the maximum voltage a capacitor can handle without failing. Exceeding this rating can lead to catastrophic failure.

3. **Tolerance**: This indicates how much the actual capacitance can vary from the stated value, expressed as a percentage. Tighter tolerances are often required in precision applications.

4. **Temperature Coefficient**: This describes how the capacitance value changes with temperature, which is crucial for applications in varying environmental conditions.

III. Electronics and Consumer Goods Industry

A. Role of Capacitors in Consumer Electronics

Capacitors are integral to the functioning of consumer electronics. They are found in:

1. **Smartphones and Tablets**: Capacitors help manage power supply, stabilize voltage, and filter signals, ensuring smooth operation of these devices.

2. **Laptops and Computers**: In computing devices, capacitors are used in power management systems, memory circuits, and signal processing, contributing to overall performance and efficiency.

3. **Home Appliances**: From refrigerators to washing machines, capacitors play a role in motor control and energy efficiency, enhancing the functionality of everyday appliances.

B. Importance in Circuit Design and Performance

In the design of electronic circuits, capacitors are essential for maintaining signal integrity and power stability. They help filter out noise, smooth voltage fluctuations, and provide the necessary energy for transient loads. As consumer electronics become more sophisticated, the demand for high-performance capacitors continues to grow.

C. Trends in Capacitor Technology for Consumer Goods

Recent trends in capacitor technology include the development of smaller, more efficient capacitors that can handle higher frequencies and voltages. Innovations such as multilayer ceramic capacitors (MLCCs) are becoming increasingly popular due to their compact size and reliability.

IV. Automotive Industry

A. Use of Capacitors in Automotive Electronics

The automotive industry has seen a significant increase in the use of capacitors, particularly in:

1. **Engine Control Units (ECUs)**: Capacitors are used to stabilize power supply and filter signals in ECUs, which manage engine performance and emissions.

2. **Infotainment Systems**: Capacitors help ensure smooth operation of audio and navigation systems, providing the necessary power for high-quality sound and reliable performance.

3. **Safety Systems (ABS, Airbags)**: Capacitors are critical in safety systems, where they provide the necessary energy for rapid deployment of airbags and other safety features.

B. Growing Demand for Electric Vehicles (EVs)

As the automotive industry shifts towards electric vehicles, the demand for capacitors is expected to rise. Capacitors play a vital role in energy storage and management systems, helping to improve the efficiency and performance of EVs.

C. Innovations in Capacitor Technology for Automotive Applications

Innovations such as supercapacitors and advanced electrolytic capacitors are being developed to meet the unique demands of automotive applications. These technologies offer higher energy density and faster charging capabilities, making them ideal for electric and hybrid vehicles.

V. Telecommunications Industry

A. Capacitors in Communication Devices

Capacitors are essential in telecommunications, found in:

1. **Mobile Networks**: Capacitors help filter signals and stabilize power in base stations and mobile devices, ensuring reliable communication.

2. **Satellite Communications**: In satellite systems, capacitors are used for signal processing and power management, contributing to the overall performance of communication networks.

3. **Fiber Optics**: Capacitors play a role in the signal conditioning and amplification required for high-speed data transmission in fiber optic systems.

B. Role in Signal Processing and Filtering

In telecommunications, capacitors are crucial for signal processing and filtering applications. They help eliminate noise and ensure that signals are transmitted clearly and efficiently.

C. Future Trends in Telecommunications and Capacitor Usage

As the demand for faster and more reliable communication continues to grow, advancements in capacitor technology will play a key role in supporting the development of next-generation telecommunications systems, including 5G and beyond.

VI. Industrial and Manufacturing Sector

A. Capacitors in Industrial Machinery

In the industrial sector, capacitors are used in:

1. **Motor Drives and Controls**: Capacitors help manage power supply and improve the efficiency of electric motors used in various industrial applications.

2. **Power Supply Systems**: Capacitors are essential for stabilizing voltage and filtering noise in power supply systems, ensuring reliable operation of industrial equipment.

B. Importance in Automation and Robotics

As automation and robotics become more prevalent in manufacturing, the demand for capacitors is increasing. Capacitors are used in control systems, sensors, and actuators, contributing to the efficiency and reliability of automated processes.

C. Energy Efficiency and Sustainability Considerations

With a growing focus on energy efficiency and sustainability, capacitors are being designed to minimize energy loss and improve overall system performance. Innovations in capacitor technology are helping industries reduce their environmental impact.

VII. Medical Industry

A. Use of Capacitors in Medical Devices

Capacitors are critical in the medical industry, found in:

1. **Diagnostic Equipment (MRI, Ultrasound)**: Capacitors help manage power supply and signal processing in diagnostic imaging systems, ensuring accurate and reliable results.

2. **Therapeutic Devices (Defibrillators, Pacemakers)**: In therapeutic devices, capacitors provide the necessary energy for rapid response, playing a vital role in patient care.

B. Reliability and Safety Standards in Medical Applications

In the medical field, reliability and safety are paramount. Capacitors used in medical devices must meet stringent standards to ensure patient safety and device performance.

C. Innovations in Capacitor Technology for Medical Use

Recent advancements in capacitor technology, such as the development of biocompatible materials and improved reliability, are enhancing the performance of medical devices and expanding their applications.

VIII. Renewable Energy Sector

A. Role of Capacitors in Renewable Energy Systems

Capacitors play a vital role in renewable energy systems, including:

1. **Solar Inverters**: Capacitors are used in solar inverters to manage power conversion and improve efficiency in solar energy systems.

2. **Wind Turbine Systems**: In wind energy applications, capacitors help stabilize power output and improve the efficiency of energy conversion.

B. Importance in Energy Storage and Management

Capacitors are essential for energy storage and management in renewable energy systems. They help smooth out fluctuations in power generation and ensure a stable supply of energy.

C. Future Developments in Capacitor Technology for Renewable Energy

As the renewable energy sector continues to grow, advancements in capacitor technology will be crucial for improving energy storage solutions and enhancing the efficiency of renewable energy systems.

IX. Conclusion

In summary, standard capacitors are integral to a wide range of industries, from consumer electronics to renewable energy. Their ability to store and manage electrical energy makes them essential components in modern technology. As industries evolve and new applications emerge, the role of capacitors will continue to expand, driving innovation and improving performance across various sectors. The future of capacitors looks promising, with ongoing advancements in technology paving the way for more efficient, reliable, and sustainable solutions.

X. References

A comprehensive list of academic papers, articles, and industry reports used for research, along with additional resources for further reading on capacitors and their applications, can be provided upon request.