What are the Popular Air Conditioner Capacitor Products?

I. Introduction

Air conditioning systems are essential for maintaining comfort in our homes and workplaces, especially during the sweltering summer months. At the heart of these systems lies a crucial component: the capacitor. Capacitors play a vital role in the operation of HVAC systems, ensuring that air conditioners start and run efficiently. This article aims to provide an in-depth understanding of air conditioner capacitors, highlight popular products in the market, and offer guidance on maintenance and replacement.

II. Understanding Air Conditioner Capacitors

A. Definition and Function of Capacitors in Air Conditioning Units

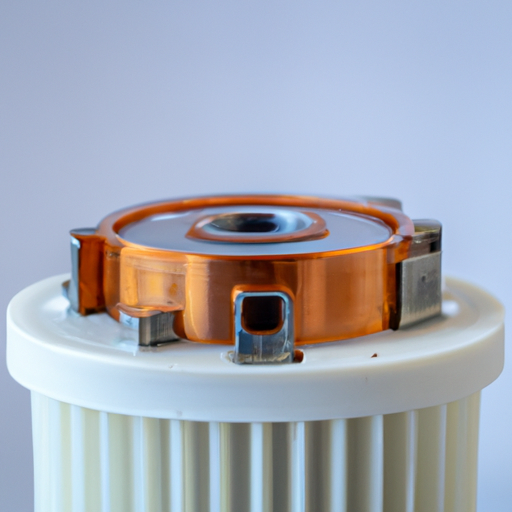

A capacitor is an electrical component that stores and releases energy. In air conditioning units, capacitors are used to provide the necessary electrical energy to start the compressor and fan motors. They help stabilize voltage and improve the efficiency of the system, ensuring that the air conditioner operates smoothly.

B. Types of Capacitors Used in Air Conditioning Systems

1. **Start Capacitors**: These capacitors provide a boost of energy to start the compressor motor. They are typically used for a short duration and then disconnected from the circuit once the motor reaches its operating speed.

2. **Run Capacitors**: Unlike start capacitors, run capacitors remain in the circuit while the motor is running. They help maintain a consistent voltage and improve the efficiency of the motor.

3. **Dual Run Capacitors**: These capacitors combine the functions of both start and run capacitors in a single unit. They are commonly used in modern air conditioning systems, providing a compact solution for both starting and running needs.

C. How Capacitors Work in Conjunction with Other Components

Capacitors work alongside other components, such as the compressor and fan motors, to ensure the air conditioning system operates efficiently. When the thermostat signals the need for cooling, the capacitor provides the necessary energy to start the compressor. Once the compressor is running, the run capacitor maintains the voltage, allowing the system to function optimally.

III. Signs of a Failing Capacitor

A. Common Symptoms of Capacitor Failure

Recognizing the signs of a failing capacitor is crucial for maintaining the efficiency of your air conditioning system. Common symptoms include:

1. **AC Unit Not Starting**: If your air conditioner fails to start, it may be due to a faulty capacitor that cannot provide the necessary energy to the compressor.

2. **Humming Noise from the Unit**: A humming sound without the unit starting can indicate that the capacitor is trying to engage but is unable to do so.

3. **Overheating of the Compressor**: A failing capacitor can cause the compressor to overheat, leading to potential damage and costly repairs.

B. Importance of Timely Capacitor Replacement

Timely replacement of a failing capacitor is essential to prevent further damage to the air conditioning system. Ignoring the symptoms can lead to more significant issues, including compressor failure, which can be expensive to repair or replace.

IV. Popular Air Conditioner Capacitor Brands

When it comes to choosing a capacitor for your air conditioning system, several reputable brands stand out in the market. Here are some of the most popular air conditioner capacitor brands:

A. Overview of Leading Brands in the Market

1. **MARS**

- **Product Range and Specifications**: MARS offers a wide variety of capacitors, including start, run, and dual run capacitors. Their products are known for their reliability and performance.

- **Customer Reviews and Reputation**: MARS has built a solid reputation among HVAC professionals and homeowners alike, with many praising their durability and efficiency.

2. **Supco**

- **Product Range and Specifications**: Supco provides a comprehensive selection of capacitors designed for various air conditioning systems. Their products are engineered for high performance and longevity.

- **Customer Reviews and Reputation**: Customers often highlight Supco's excellent customer service and the reliability of their products, making them a popular choice in the HVAC industry.

3. **GE (General Electric)**

- **Product Range and Specifications**: GE is a well-known brand that offers a range of capacitors suitable for residential and commercial air conditioning systems. Their products are designed to meet high industry standards.

- **Customer Reviews and Reputation**: GE has a long-standing reputation for quality and innovation, with many users appreciating the performance and reliability of their capacitors.

4. **Dayton**

- **Product Range and Specifications**: Dayton manufactures a variety of capacitors, including dual run capacitors that are popular in many HVAC applications. Their products are known for their robust construction.

- **Customer Reviews and Reputation**: Dayton is recognized for its high-quality products and has garnered positive reviews from both professionals and DIY enthusiasts.

5. **A.O. Smith**

- **Product Range and Specifications**: A.O. Smith offers a selection of capacitors designed for air conditioning systems, focusing on energy efficiency and performance.

- **Customer Reviews and Reputation**: Customers appreciate A.O. Smith's commitment to quality and innovation, making them a trusted name in the HVAC industry.

V. Key Features to Consider When Choosing a Capacitor

When selecting a capacitor for your air conditioning system, several key features should be considered:

A. Voltage Rating

Ensure that the capacitor's voltage rating matches the requirements of your air conditioning unit. Using a capacitor with an incorrect voltage rating can lead to failure and potential damage to the system.

B. Microfarad (µF) Rating

The microfarad rating indicates the capacitor's capacitance. It's essential to choose a capacitor with the correct µF rating specified by the manufacturer to ensure optimal performance.

C. Physical Size and Mounting Options

Consider the physical size of the capacitor and its mounting options. Ensure that the new capacitor fits within the designated space in your air conditioning unit.

D. Durability and Temperature Ratings

Look for capacitors that are designed to withstand high temperatures and harsh conditions. A durable capacitor will have a longer lifespan and require less frequent replacement.

E. Warranty and Customer Support

Choose a brand that offers a warranty and reliable customer support. This can provide peace of mind and assistance in case of any issues with the product.

VI. How to Replace an Air Conditioner Capacitor

Replacing a failing capacitor can be a straightforward process if done safely and correctly. Here’s a step-by-step guide:

A. Safety Precautions Before Starting the Replacement

1. **Turn Off Power**: Before starting any work, ensure that the power to the air conditioning unit is turned off at the circuit breaker.

2. **Discharge the Capacitor**: Use a screwdriver with an insulated handle to discharge the capacitor by shorting the terminals. This step is crucial to avoid electric shock.

B. Tools Required for the Replacement Process

- Screwdriver

- Multimeter (for testing)

- Insulated gloves

- Replacement capacitor

C. Step-by-Step Guide to Replacing a Capacitor

1. **Disconnecting Power**: Ensure the power is off and the capacitor is discharged.

2. **Identifying the Capacitor**: Locate the capacitor in the air conditioning unit. It is usually cylindrical and may be mounted on the compressor or inside the electrical panel.

3. **Removing the Old Capacitor**: Carefully disconnect the wires from the old capacitor, noting their positions for reinstallation. Remove the capacitor from its mounting.

4. **Installing the New Capacitor**: Position the new capacitor in place and connect the wires according to the notes taken earlier. Ensure the connections are secure.

5. **Testing the System**: Restore power to the unit and test the air conditioning system to ensure it operates correctly.

VII. Maintenance Tips for Air Conditioner Capacitors

To prolong the life of your air conditioner capacitors, consider the following maintenance tips:

A. Regular Inspection and Testing

Periodically inspect the capacitors for signs of wear or damage. Testing the capacitors with a multimeter can help identify potential issues before they lead to failure.

B. Importance of Keeping the Unit Clean

Keep the air conditioning unit clean and free from debris. A clean unit operates more efficiently and reduces the strain on the capacitors.

C. Signs That Indicate the Need for Professional Servicing

If you notice persistent issues with your air conditioning system, such as unusual noises or inconsistent cooling, it may be time to call a professional for servicing.

VIII. Conclusion

Air conditioner capacitors are essential components that ensure the efficient operation of HVAC systems. Understanding their function, recognizing the signs of failure, and knowing how to choose quality products can help you maintain your air conditioning unit effectively. By selecting reputable brands and performing regular maintenance, you can extend the life of your capacitors and ensure your air conditioning system runs smoothly for years to come. As technology advances, we can expect even more efficient and durable capacitor designs in the future, further enhancing the performance of air conditioning systems.

IX. References

- HVAC industry publications

- Manufacturer websites for MARS, Supco, GE, Dayton, and A.O. Smith

- Home improvement and DIY resources

- Professional HVAC technician insights

This comprehensive guide aims to equip you with the knowledge needed to understand, select, and maintain air conditioner capacitors effectively. Whether you're a homeowner or an HVAC professional, being informed about these critical components will help you ensure optimal performance and longevity of your air conditioning system.